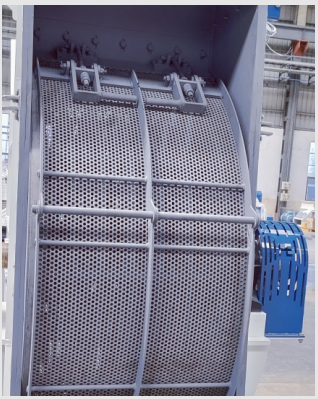

Hammer Mill

Hammer mill is used for raw grinding to get finesse particle.

Capacity - upto 30 TPH

Hammer Mill used to break and grind materials into fine particles (size reduction). A hammer mill is a steel drum containing a rotating rotor on which hammers are mounted. The hammers are free to swing on the ends of the cross or fixed to the central rotor. The rotor spins at a high speed inside the drum while material is fed through rotary feeder. The material is impacted by hammer (beaters) and is hereby break, grind and expelled through screens in the drum of a selected size. Our Hammer mills can give outputs upto 30 TPH on coarse grinding & upto 20 TPH on fine grinding or depending on the screen size.

Product Applications

- Feed Industry (Cattle, Poultry and Aqua)

- Solvent Plant

- Milling Industry (Rice, pulses, Flour)

- Ethanol Plant

- Biomass Plant

Key Features:

- Magnet in the inlet of hammer mill to avoid invasion of iron material in milling chamber

- Easy replacements of sieves & beaters.

- Hammer mill doors are interlocked with safety device to avoid any accident during rotation of rotor

- Option available for additional features like temperature sensor for hammer mill chamber, main bearing and motor, vibration sensor for hammer mill.

- Easy opening and closing of sliding door for maintenance.

- Provided with aspiration system for increase the through put by 10% and to avoid the clogging of sieves while doing fine grinding.

- Online change in direction of rotation for rotor while running the mill (i.e., clockwise, or anti-clockwise)

- Hammer mill sieves are available with more opening areas upto 60%

- Option available for Frequency controller for hammer mill with drive compatible motor.

- Hammer mill feeder synchronized with running current of hammer mill motor.

Our Projects

Our Recent Success in Feed Mill Turn-Key Project

24

+Awards Won

12

+Years Experience

352

+Happy Clients

Our Gallery

Explore our recent projects

Get In Touch

Don't hesitate to contact us

Call Us

Write to us